1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1:Keywords:

Preparation of Capacity and Power Batteries

Produce soft wrapped wound battery cells

2:Product Introduction:

This product is mainly used for the production of soft wrapped battery cells and can be used to prepare two types of batteries: capacity batteries and power batteries. Through these processes, the battery's room temperature discharge performance, self discharge performance, storage performance, rate charge discharge performance, high temperature performance, low temperature performance, and safety performance (including squeezing, needle punching, collision, overcharging, and overdischarging) can be tested. In addition, the experimental line can also conduct life assessment and health status detection of lithium-ion batteries

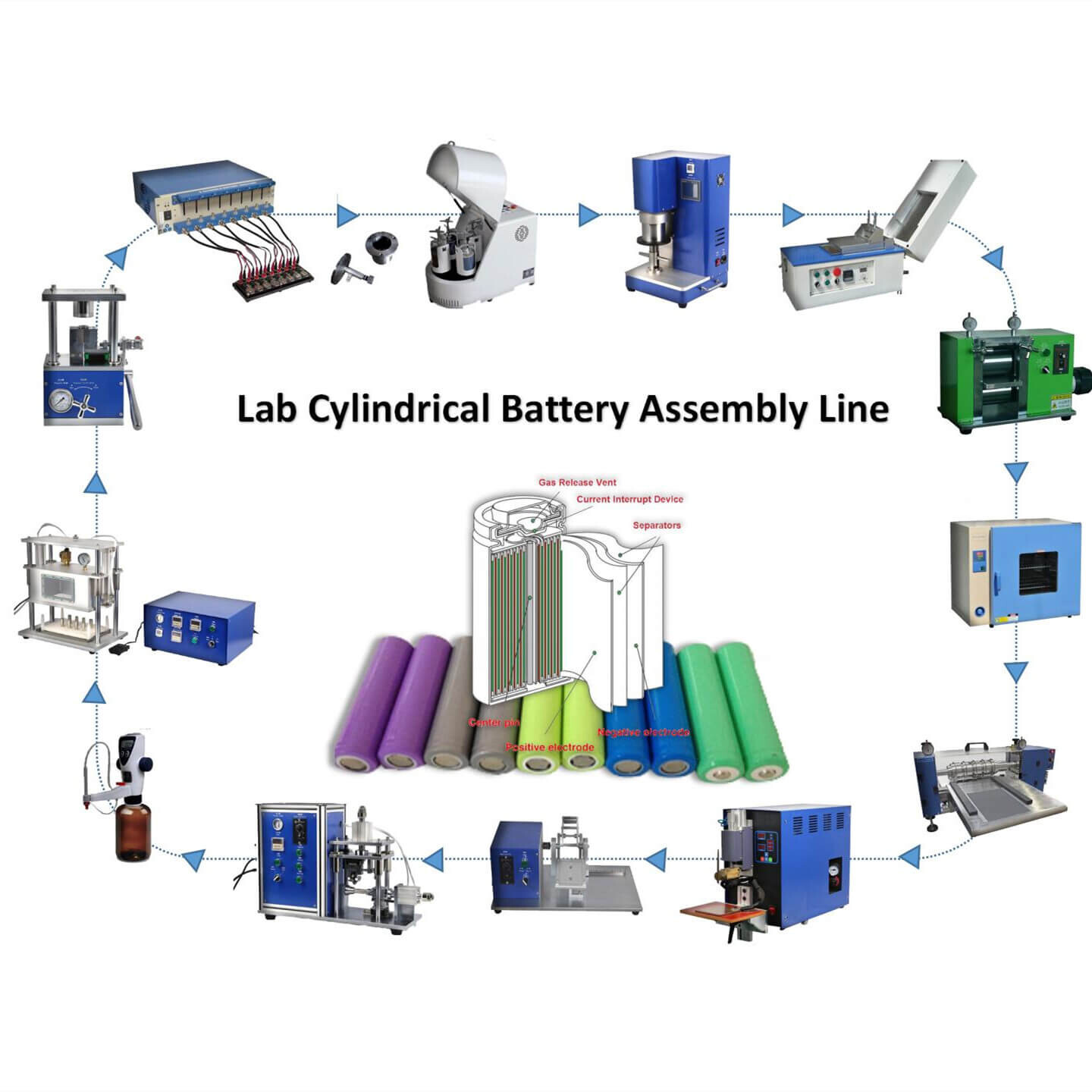

3:Process Flow:

Homogenate stirring

Positive/negative electrode homogenate

Coating process

Polar forming

Battery assembly

Battery testing

4:Major Equipment:

Tube furnace/box furnace

Planetary ball mill

Vacuum mixer

Heating coating machine/coating machine

Heating roller press

Polar die cutting machine

Manual laminating machine/semi-automatic laminating machine

Ultrasonic spot welding machine

Aluminum plastic film forming machine

Top side heat sealing machine

Water oxygen glove box

Injection pump/pipette

Vacuum static box

Vacuum sealing machine

5V6A 8-channel tester

Final sealing machine

5:Applications:

Electronic devices

Medical equipment

Electric vehicle

Energy storage

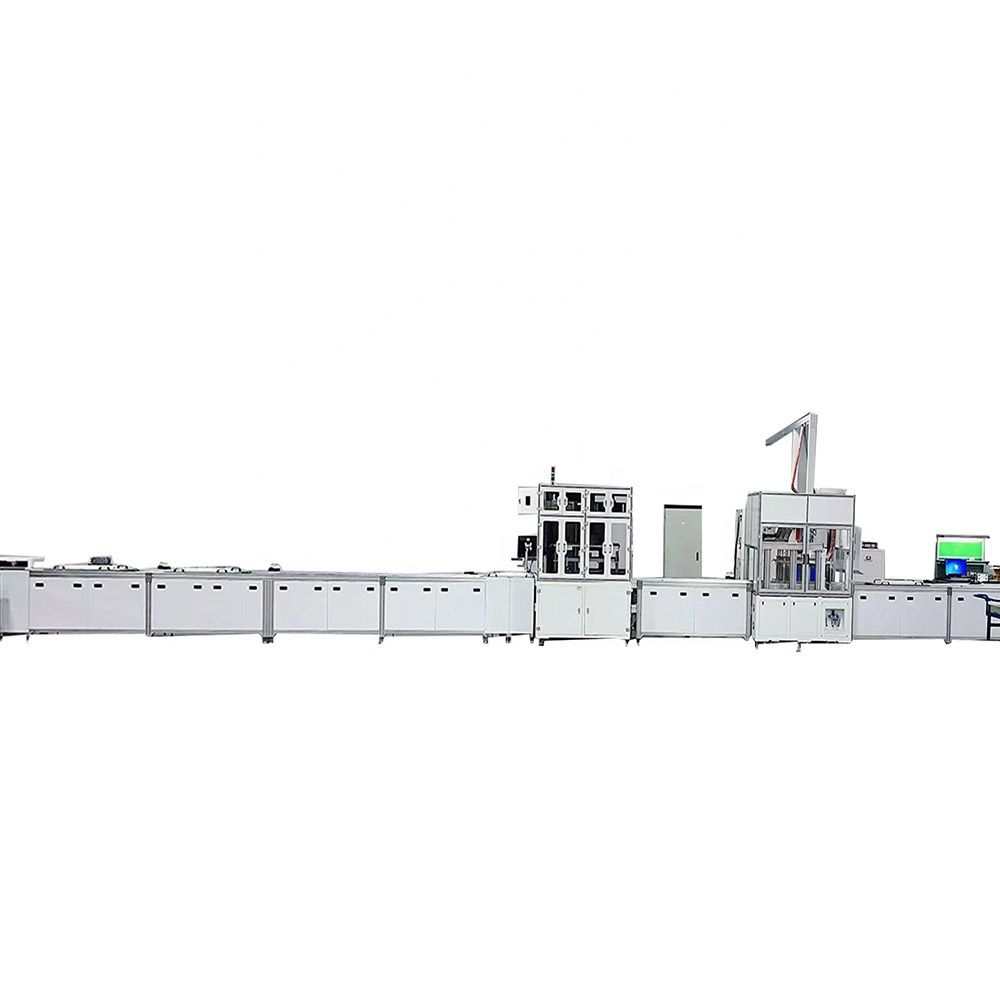

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support